“WIKA knows that technology keeps on changing and upgrading”

WIKA India operates and manufactures with a stringent quality

and environment management system according to requirements of international

standard (ISO 9001, ISO 14001). While its facilities use modern machinery,

state-of-the-art manufacturing facilities and certified calibration and testing

instruments towards ensuring quality control and least risk operations, WIKA

India has NABL accreditation and is equipped with high level primary standard

calibration equipment for calibrations. In an interaction with Mr. Prashant Sinha, Head of Marketing, WIKA India about the role of Industrial

IoT and smart instrumentation technology.

How is Smart Instrumentation Technology transforming with Cloud

Computing?

Smart instrumentation technology is undergoing a

significant upgrade through its collaboration with cloud computing. This

combination is proving to be super beneficial in several industries because it

is making things better and more efficient.

One of the most important part of this upgrade is how

data is collected, stored and used. Smart instruments make a ton of data, and

cloud computing is like a big storage and management system for all that data.

It also helps analyse that data and accordingly make decisions.

Another benefit of this combo is that the users can

now monitor and control smart instruments in real-time. Cloud computing lets

you send data from the instruments to the cloud so that you can make quick

decisions and respond fast to any changes.

Cloud-based solutions help with predicting when

equipment might break. By looking at past data, businesses can figure out when

something might go wrong and fix it before it causes any major problem. This

allows businesses to plan maintenance activities and avoid downtime.

How has Industrial IoT (IIoT) played a crucial role in the

transformation of routine business?

The Industrial Internet of Things (IIoT) has changed

the way many businesses operate. It involves using smart technology in

industries that helps make things work better. By adding these smart devices to

their machines and systems, several businesses have seen major improvements in

how well they work. One of the significant changes that IIoT has brought is

that the businesses can now use data to make decisions, which helps them run

their operations more smoothly and efficiently.

IIoT has also brought a big difference in predicting

when machines might have problems and improving quality control. By keeping a

track on their performance, businesses can fix any issues before they become

major, thereby, saving time and money as well as reducing waste.

IIoT helps make workplaces safer by keeping an eye on

the environment and machines, making it easier for businesses to take safety

measures quickly.

IIoT has also helped businesses manage their supplies

better by keeping track of products in real-time and making sure that they have

what they need on the right time.

The energy consumption in industries has also

undergone a significant change. IIoT lets businesses control the amount of

energy they use as well as help them find ways to save funds. This is also

beneficial in terms of enabling remote management of any business operations.

How does WIKA aim to bridge the expectations of Industry 4.0?

IIoT is heavily dependent on real-time data,

automation, and interconnectivity. The absence of these would not let the

technology provide the desired support.

In the era of this advanced and data-driven technology

and automation, WIKA plans to put up the smart sensors in its products to keep

up with the latest technology. These sensors will watch over things, detect

problems, and give important information to make decisions.

A significant transformation implemented by WIKA in

its operations involves integrating its products with the Internet of Things

(IoT). This means that our tools can communicate with one another, exchange

information, and seamlessly collaborate. WIKA also understands that keeping a

check on data and implementing maintenance practices ahead of time is important

in data-driven technology. Therefore, we use data collected from the tools to

check how well things are operating and start maintenance activities on time so

that nothing gets affected.

Since there is a lot of data available with these

advanced technologies, WIKA uses Cloud Computing to store, process, and study

this data efficiently. We also use this technology to make our tools better at

managing data. We also focus on creating tools that can meet the needs of

different industries as well as work well in different situations.

WIKA also considers safety as utmost important.

Therefore, we do a lot to protect our tools and the information we have in

different ways such as, enabling interaction between tools, putting a code on

the information, and regularly updating them.

WIKA knows that technology keeps on changing and

upgrading. Therefore, we invest a lot of time and finance on research and

development to stay at the front of technology. We ensure that our products are

always good for the changing world of data-driven technology. WIKA is doing all

these things to not just keep up with Industry 4.0 but to be even better than

what's expected.

How is IIoT helping WIKA in serving a wide variety of industries?

IIoT is helping WIKA in serving a wide variety of

industries by offering several benefits. Some of these include real-time

monitoring, enabling automation of menial, time-consuming tasks, enabling

end-to-end encryption and bidirectional communication, diagnosis documentation

of data, automating maintenance, and unnecessary cost reduction.

WIKA IIoT solutions encompass the complete value

chain, from the installation of sensors, measuring instruments, and gateways to

establishing a secure connection to either the cloud or local data servers.

Additionally, these solutions include the individual configuration of your

application and training for your staff.

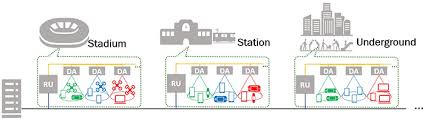

Our NETRIS radio units and IIoT gateways that make

your existing measuring instruments network-capable, support for innovative

LPWAN standard and helping customers in setting up a private LoRaWAN network

with LORIOT servers or other hosts, the WIKA IIoT cloud that enables device

management, data acquisition, data storage, and the creation of an

application-specific digital twin, and other IIoT application solutions help

increase efficiency and achieve added value.

With such a powerful, robust, and flexible IIoT

solutions, we are able serve a wide variety of industries like machine building

automation, process industry, food & pharma, power transmission &

distribution, and HVAC, to name a few.

In your opinion, what are the roadblocks in the implementation of

smart instrumentation in the smart industry?

Although smart instrumentation is the need of the

hour, the industry faces several roadblocks in the way. One of the most

significant one is the cost to set up because it needs smart sensors,

communication equipment, and data systems, which can be financially burdensome

for some businesses. What might add on to this cost is trying to make the old

systems work seamlessly with the new ones. This can be hard and might need more

money to upgrade things.

It is also important to keep the data safe from

cyber-attacks when more devices become interconnected. Another important aspect

is to set some universal standards for communication protocols and data

formats, which is really important to make things work smoothly.

Another roadblock is training people with skills on

how to use and take care of smart instruments, keeping data safe from hackers,

and other aspects of technology. It is also important to be prepared to handle

situations when smart instruments stop working or break as this might impact

the overall productivity and workflow.

It is also possible that in some places, especially

far off, it gets hard to have enough power and good internet available for

smart instruments to work well. Ensuring a consistent power supply and reliable

internet connectivity can be a major challenge.

Leave A Comment