Intel Accelerates Software-Defined Innovation with Whole-Vehicle Approach

Intel, at CES 2025, unveiled an expanded

product portfolio and new partnerships designed to accelerate automakers'

transitions to electric and software-defined vehicles (SDVs). Intel now offers

a whole-vehicle platform, including high-performance compute, discrete

graphics, artificial intelligence (AI), power management and zonal controller

solutions alongside the Intel Automotive Virtual Development Environment (VDE)

co-developed with Amazon Web Services (AWS). Intel's approach addresses

automakers' cost and performance scalability challenges, enabling faster, more

efficient and more profitable SDV development and deployment.

"Intel automotive is bringing innovative solutions that

reduce cost in the SDV revolution. Our whole-vehicle approach, combined with

cloud integration, delivers a complete solution that drives down total cost of

development and deployment while empowering automakers to build the future of

mobility faster, more efficiently and more profitably," said Jack Weast,

Intel Fellow, vice president and general manager of Intel Automotive.

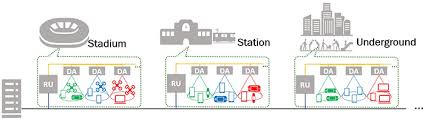

Intel's whole-vehicle platform reduces inefficiencies of

traditional fragmented approaches to vehicle architectures. By optimizing the

entire vehicle's electrical/electronic architecture, Intel drives significant

cost reductions and performance improvements.

Supporting this platform, Intel introduced the availability

of the Adaptive Control Unit (ACU), designed for electric vehicle (EV) power

trains and zonal controller applications.

The ACU U310 is a new kind of processing unit that supports

the consolidation of multiple real-time, safety-critical and cybersecure

functions, applications and domains (X-in-1) into a single chip. Traditional

time and sequential processing-based micro and zonal controllers struggle to

handle multiple workloads due to limited deterministic processing capabilities.

In contrast, Intel's new family of ACU devices integrates a flexible logic area

that offloads real-time control algorithms from the CPU cores, ensuring

reliable performance, freedom from interference (FFI) and deterministic data

delivery even when consolidating multiple microcontroller workloads into a

single zonal MCU. This dual-brain approach enables greater workload

consolidation, lowers cost and enhances safety, cybersecurity and performance.

When used in an electric vehicle power train, the ACU U310

supports advanced algorithmic solutions that reduce vehicle energy demand from

the battery, automatically adapting high voltage and control frequencies to

individual driver styles and road conditions.

The ACU reduces cost per kilowatt and enhances energy

efficiency, allowing the vehicle to reclaim up to 40 percent of the power train

system energy losses, delivering a 3 percent to 5 percent efficiency boost

during the Worldwide Harmonized Light Vehicles Test Procedure (WLTP). This

translates to increased range, faster charging and a more responsive driving

experience, while significantly reducing per-vehicle bill of materials (BOM),

electric motor size and battery costs compared to traditional approaches.

Stellantis Motorsports selected Intel as a key technology

partner and is adopting the Adaptive Control technology into its

next-generation inverter control for enhanced performance and efficiency in

competitive racing environments. In this implementation, the Intel technology

will control the electric motor and recover energy during braking phases. The

inverter plays a crucial role during a Formula E race, where any gain in

efficiency is transformed into a precious competitive advantage.

Karma Automotive announced support for Intel's ACU,

showcasing an Intel co-branded inverter featuring Optimal Pulse Pattern control

algorithms to improve efficiency and enable four unique driving profiles,

including innovative features like Torque Ripple Reduction and Range Boost.

The ACU's programmability allows it to serve as a

first-of-its-kind software-defined zonal controller, adapting to different

vehicle topologies and applications. This flexibility streamlines the

transition to software-defined vehicles, simplifies supply chains and reduces

the complexity of the vehicle BOM.

Leave A Comment