GlobalLogic & Ericsson Deploy Private 5G Network at Hitachi Rail’s State-of-the-Art Digital Factory

GlobalLogic

Inc., a Hitachi Group company and leader in digital engineering, has

designed and deployed a state-of-the-art 5G private network at Hitachi Rail’s most

digitally advanced facility in Hagerstown, Maryland, USA. Implemented in

collaboration with Ericsson, the 5G network serves as the digital foundation

for the 307,000 square foot factory, enabling advanced automation, worker

safety, and the scalability of innovative industrial solutions.

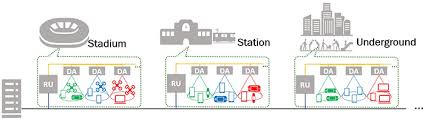

Private 5G could enable next-generation industrial capabilities, such

as:

· Physical AI, enabled by real-time data capture and

analysis, allows intelligent systems—such as inspection robots or robot dogs—to

detect defects and even support on-site additive manufacturing for spares and

tooling.

· Digital twins, powered by high-bandwidth,

low-latency connectivity, enable engineers to simulate and optimize railcars

before production, thereby reducing errors and accelerating time to market.

· Predictive maintenance, driven by secure, real-time

data over private wireless, helps anticipate failures, reduce downtime, and

optimize equipment performance.

· Automated quality inspections, using advanced image

analysis, ensure faster, more accurate defect detection and improved product

reliability.

· IoT-driven material transport, enabled by seamless

connectivity, allows automated vehicles and devices to move materials safely

and efficiently across the factory floor.

With ultra-low latency and high bandwidth at its core, the 5G private

network enables real-time execution of critical processes, driving significant

gains in efficiency, precision, and worker safety. The Hagerstown facility,

capable of producing up to 20 railcars each month, is strategically positioned

to meet the growing demand for advanced rail manufacturing across North America

—while setting a new benchmark for digital-first, smart manufacturing.

“Our new digital factory in Hagerstown is more than just a train

manufacturing site – it is a blueprint for the future of rail production

worldwide, harnessing the latest AI, robotics, and digital systems to deliver

high-quality, smart, and reliable manufacturing. The project exemplifies true

One Hitachi, integrating IT, OT, and product capabilities with digital to

accelerate the creation of unique value on a global scale,” said Joe

Pozza, President of North America, Hitachi Rail. “Private 5G

connectivity is a game-changer for advanced manufacturing environments. This

secure, high-performance connectivity allows us to automate more processes,

protect our workforce, and accelerate innovation.”

“To make Industry 4.0 real, manufacturers need secure, high-performance

connectivity that is flexible and scalable. This project in Hagerstown shows

how private 5G can power everything from predictive maintenance to

collaborative robotics, while reducing energy usage and downtime,” said Alan

Minney, Senior Director of Global Strategic Partnerships for Enterprise at

Ericsson. “We are proud to partner with GlobalLogic and Hitachi Rail

to demonstrate the impact of 5G on sustainable manufacturing in the United States.”

GlobalLogic leveraged its extensive cross-industry expertise–spanning

telecommunications and manufacturing— along with advanced digital capabilities

from semiconductor-level to cloud solutions, and our more than a decade-long

partnership with Ericsson to support this ambitious and demanding project

fully. As an official Ericsson Private 5G ecosystem partner, GlobalLogic was

responsible for technical and business consulting, full deployment and

integration of the private 5G network into the plant’s processes, as well as

complete network lifecycle management and end-to-end service delivery.

“Private 5G networks are unlocking new opportunities for industries,

from advanced automation to energy optimization. Building on our partnership

with Ericsson and working closely with the Hitachi Rail team, we are delivering

ultra-reliable, low-latency, and secure wireless connectivity, “said Sameer

Tikoo, GVP Communications & Network Provider Business Unit at

GlobalLogic. “It’s more than faster connectivity—it’s about

establishing the resilient digital backbone that modern industrial operations

need to compete, grow, and achieve sustainability goals.”

The project demonstrates that the synergy of Hitachi Group expertise,

Ericsson’s advanced solutions, and GlobalLogic’s comprehensive approach can

transform the industrial industry toward smart, safe, and sustainable factories

of the future.

Leave A Comment